The Nuxoll Lab has introduced a new approach to tackling bacterial biofilm infections on medical implants: We aim to thermally treat the biofilm in situ using a polymer / magnetic nanoparticle composite coating which converts magnetic field energy into localized heat. Our long-term goal for this technology is to replace most explanation and reimplantation surgeries with a non-invasive outpatient procedure based on a carefully designed composite coating.

The Nuxoll Lab is developing an elegant materials-based approach to automated pulsatile drug delivery. By stacking sacrificial barriers alternately with individual doses of drug, we build laminates which release the doses in discrete pulses. Different drugs can be loaded into each layer and the barriers can be tuned to specific delay times, allowing, for instance, rapid assembly of personalized drug delivery chips from an assortment of pre-made polymer films. Our long-term goal for this technology is the replacement of extended injection regimens (e.g., vaccination series or allergy treatments) with a single quickly-inserted polymer laminate. There are at least two potential paths towards this goal, both of which involve carefully designed polymer composites to manipulate competing rate processes for controlled release.

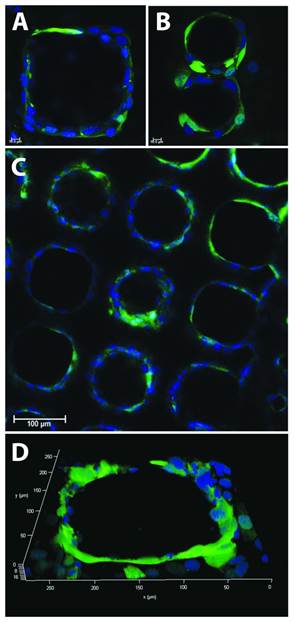

While mechanical and electrical medical implants are common, there are very few implantable drug delivery systems and no implantable chemical sensors which function for more than a week (Nuxoll, Adv Drug Deliv Rev, 2013). The body identifies the foreign device and encapsulates in fibrous material, strongly altering the mass transport between the device and the body. Encouraged by results from tissue engineers using scaffolds with well-defined pore structure, we aim to create a membrane which the body will colonize with capillaries, bypassing the fibrotic response and placing any device beneath the membrane in direct, permanent contact with the patient’s bloodstream—this is a high-risk, high-reward project. Our approach uses silicon microfabrication to create a 50 µm thick membrane full of identical, regularly-spaced pores with submicron precision. We have demonstrated that endothelial cells will colonize these membranes, quickly forming tube-like structures which presage capillary development, and have determined the optimum pore diameter (75-100 µm) (Worthington, J Biomed Mater Res B, in press).

A-C) Representative sub-surface images and D) a three-dimensional rendering of GFP-positive murine endothelial cells cultured on wafers with pore diameters of 40 µm (A), 120 µm (B), 80 µm (C) and 200 µm (D) at various pore spacings. Endothelial cells readily organize and form tubular rings that encompass individual pores and extend through the thickness of the membrane (D). Scale bars = 10 μm (A-B) and 100 μm (C). Images taken at 63X (A-B) and 20X (A). from J.Biomed.Mater.Res.B (in press).